The Path to Perfect Propulsion

Clinicians can maximize wheelchair propulsion efficiency through personalized configuration, careful selection of parts and accessories, and effective education on propulsion techniques.

Clinicians can maximize wheelchair propulsion efficiency through personalized configuration, careful selection of parts and accessories, and effective education on propulsion techniques.

From the first stroke of the day to the last, the perfect wheelchair should support and empower clients to lead fulfilling lives. Contrary to popular belief, the task of issuing the perfect wheelchair does not end with the evaluation. Wheelchair efficiency should be maximized at every stage of the wheelchair delivery model to ensure client goals and quality of life are achieved.

How a user’s hand strikes the handrim does not happen by chance. It is an accumulation of factors both within the individual’s body and the chair build. From the client’s posture and active shoulder range of motion to the chair’s wheel size and axle position, many factors play a role in how and where the client makes contact with the wheel.

Less than ideal contact with the wheel, thousands of times a day, can have detrimental effects on shoulder health. In general, shoulder pain prevalence in wheelchair users ranges from 70-100%. The degree of pain and disability is directly proportional to the wheelchair user’s age and time since injury. Specifically considering the effects of posture and alignment, nearly 75% of paraplegics with shoulder pain suffer from impingement syndrome. Shoulders were not meant to be weight bearing joints. Years of transfers, weight shifts, and wheelchair propulsion inevitably take its toll. These numbers do not mean the battle for shoulder preservation is lost.

By ensuring adequate posture and alignment of the upper extremity with the wheel, inevitable damage can be delayed, and the extent of the damage can be lessened. Mobility is not just affected by shoulder injury; mobility is significantly limited throughout the duration of the surgical intervention and rehabilitation process. To preserve independence and health short and long term, clients cannot afford to settle for a chair that is not perfect for them.

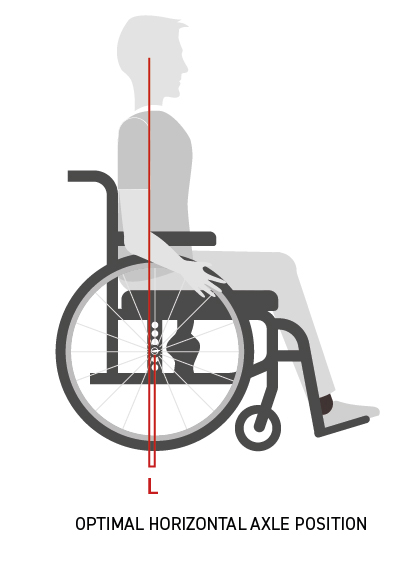

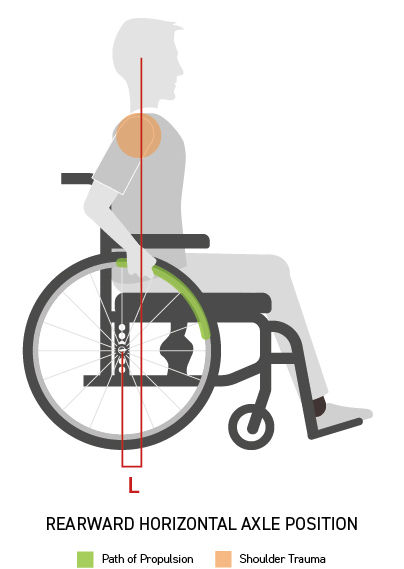

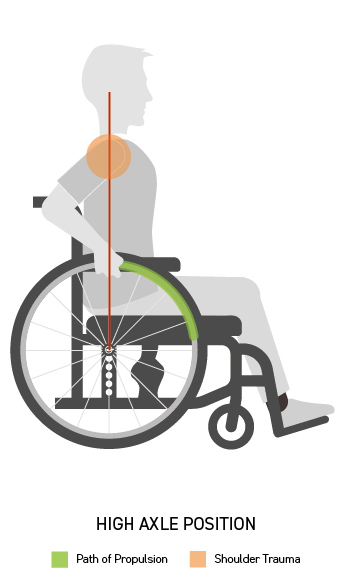

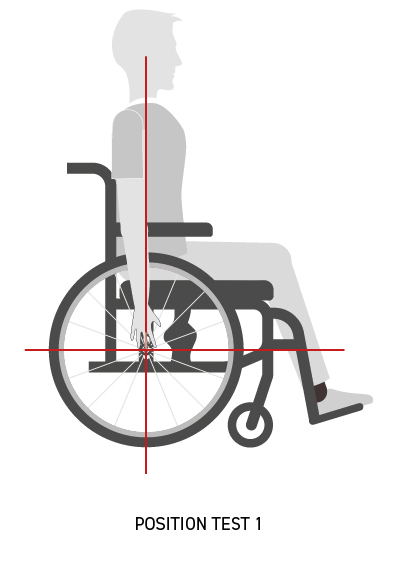

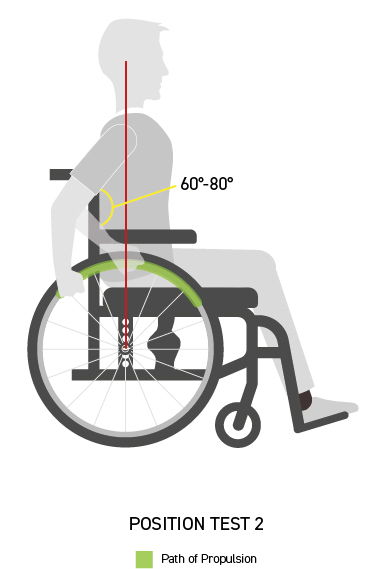

Adequate alignment of the client’s body with the chair can help delay onset of shoulder dysfunction by promoting shoulder movement through the most mechanically advantageous range. By operating the wheelchair in the optimal position, clients can go farther longer with less damage to the shoulders. Proper horizontal wheel axle positioning on the chair relative to the client’s anatomy can play a major role in delay or prevention of shoulder injury. When the wheel axle is placed too far back, say against the back post of the wheelchair frame, the client must crank their arm to nearly max shoulder extension to place the hand at the starting position. Additionally, in order to overcome friction and initiate movement between the wheels and the floor, the client must produce a large amount of force at the end range of motion. Throughout thousands of pushes a day over many years of wheelchair use, this type of positioning and propulsion will create lasting irreparable damage to the structures of the shoulder. In addition to injury, the client, unable to produce an effective stroke, must perform more strokes to cover the same distance as a well-positioned wheelchair user in a well configured wheelchair. And lastly, the issue of fatigue. Clients who needlessly work this hard for mobility find fatigue to be a major obstacle for achieving personal goals and quality of life. Something as simple as the position of the wheel axle on a wheelchair is so important that clinicians, mobility specialists, and suppliers, are all responsible for not only ordering a great chair but ensuring that at delivery it is truly the perfect chair for the client. Reassess axle position at delivery as a commitment to quality care.

To achieve ideal horizontal wheel axle placement, the axle should be moved as far forward as possible without compromising the safety and stability of the user. More often than not, people err on the side of caution and swing the opposite direction. Unfortunately, the default is to set the axle rearward to the back post of the chair. A chair with such a set up can feel up to 10 lbs heavier than it actually weighs. Also, having the fulcrum so far back prevents even skilled wheelchair users from performing wheelchair skills, such as popping wheelies over door sills and sidewalk cracks.

The axle should be at or just in front of the shoulder. With any adjustments of this nature, anti-tippers should be used as a safety precaution. During propulsion, the shoulder will now move through a mechanically advantageous range of motion while minimizing damage. In this ideal configuration, the wheelchair will feel more responsive and agile. Once wheelchair skills are learned, the client can easily raise the casters off the floor to clear obstacles they cannot propel through. The functional possibilities are endless for a motivated user in a well configured high performance chair.

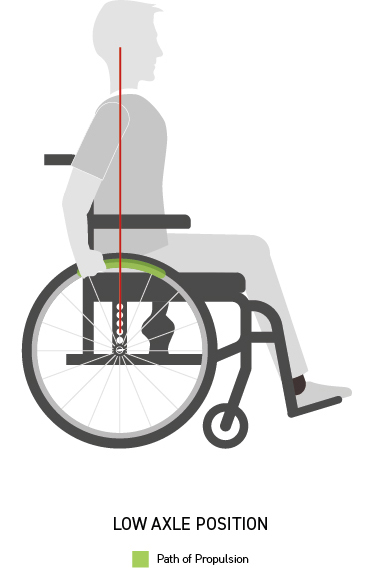

The vertical axle position is crucial for stability of the client, protection of shoulder health, and efficiency of propulsion stroke. When clients sit too low in the chair, they must hike the shoulders into elevation and nearly max extension, resembling a chicken wing, in order to place the hands on the handrim at the starting position. This repeatedly applies force to the shoulder in a vulnerable and mechanically disadvantageous position and builds fatigue. On the other hand, sitting too high may make the users top heavy and make contacting the handrim difficult. To achieve ideal vertical axle placement, the center of the axle should align with the tip of the clients’ third finger when arms are at their side. Furthermore, when the hand is at the top of the handrim, 60-80 degrees of elbow flexion should be present.

Propulsion efficiency can be maximized through parts and accessories that the client uses to drive the chair. The pages of an order form hold opportunities and features that can make a real difference in the client’s quality of life.

Clients with one sided upper extremity dysfunction preventing bilateral wheelchair propulsion often compensate with the lower extremities to drive and steer. The one arm drive is a more effective method of propulsion that allows the user to propel both wheels with the unaffected upper extremity. Clients can achieve forward, backward, and bilateral turning motion through two pushrims on the client’s functional side.

For users with decreased hand dexterity that are unable to squeeze the push rim of the wheel to propel, they may benefit from a high friction grip handrim to improve responsive control of the wheel. The Air Grip from Motion Composites is a high friction handrim solution that is safe, effective, and stylish. The handrim coating wears smooth to protect the hand and is available in vibrant colors to reflect individuality. Wheelchair gloves may be used to protect the skin from the high friction surface at high speeds.

Natural Fit handgrip accessories are made up of an oval shaped component and contoured thumb piece. The shape of the natural fit, paired with an appropriately configured chair, support more ergonomic positioning of the hand and wrist during propulsion.

If spokes are a safety concern, consider spoke guards. Spoke guards are a shield placed across the spokes of each wheel to protect the user’s fingers. A confident propeller wastes less energy than one who is afraid to hurt their fingers during each stroke. Spoke guards can be personalized to reflect the user’s personality.

Users who lack the endurance and agility to ascend inclines in the community may find grade aids, or hill holders, are just the ticket. When engaged, the grade aid allows the user to propel forward but blocks the chair from rolling backwards. This device can promote safety and confidence with uphill wheelchair propulsion in the community.

Wheelchair skills are as much about can the user propel as it is how the user propels. More often than not, in the clinic setting, it is viewed as a victory if the client can initiate movement, travel 150 feet, turn, and stop. Concern is focused on mobility and short term safety. However, the techniques used become habit and can lay the groundwork for shoulder dysfunction in the future. Think long term safety, i.e. shoulder health, during the next wheelchair appointment.

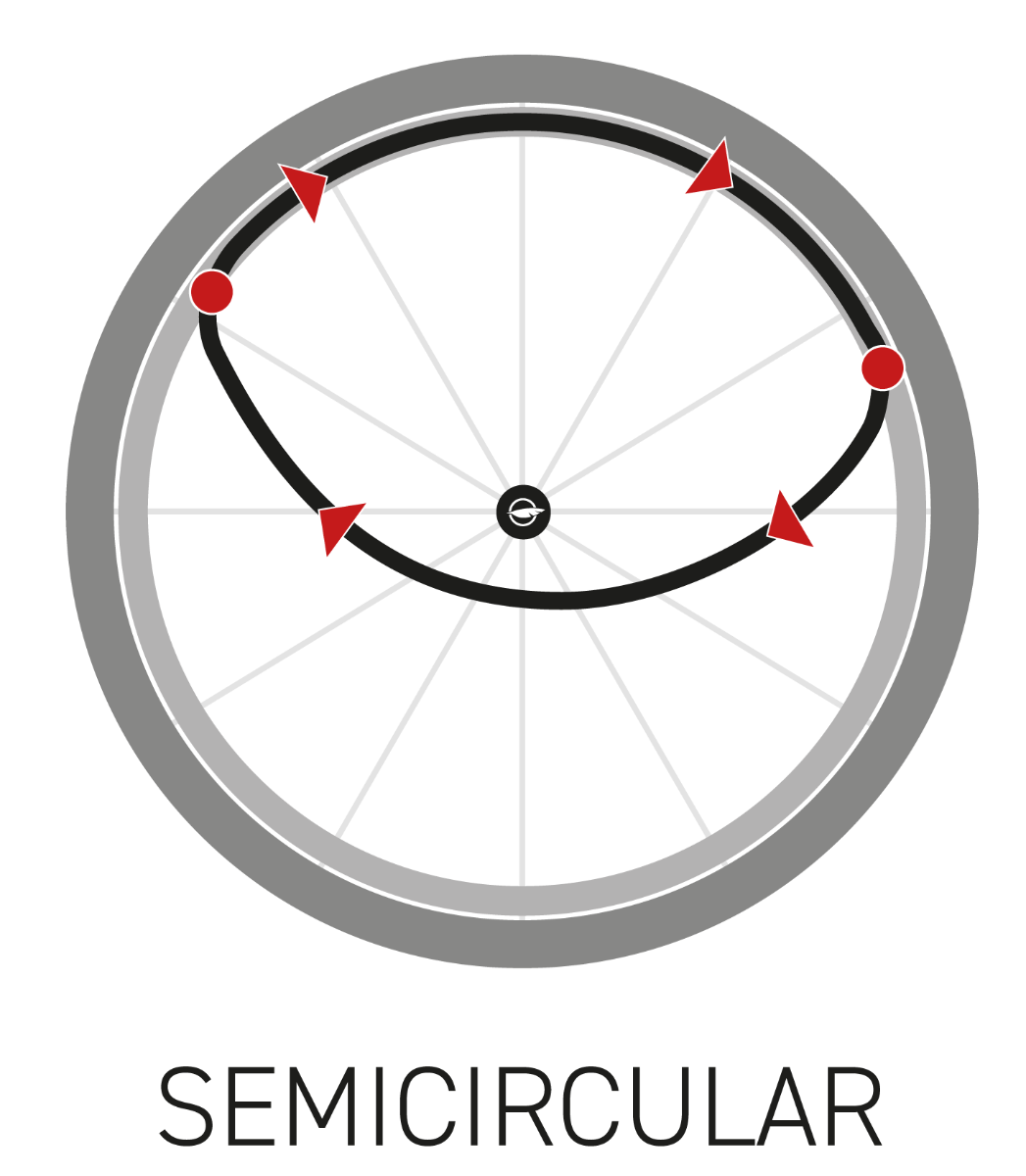

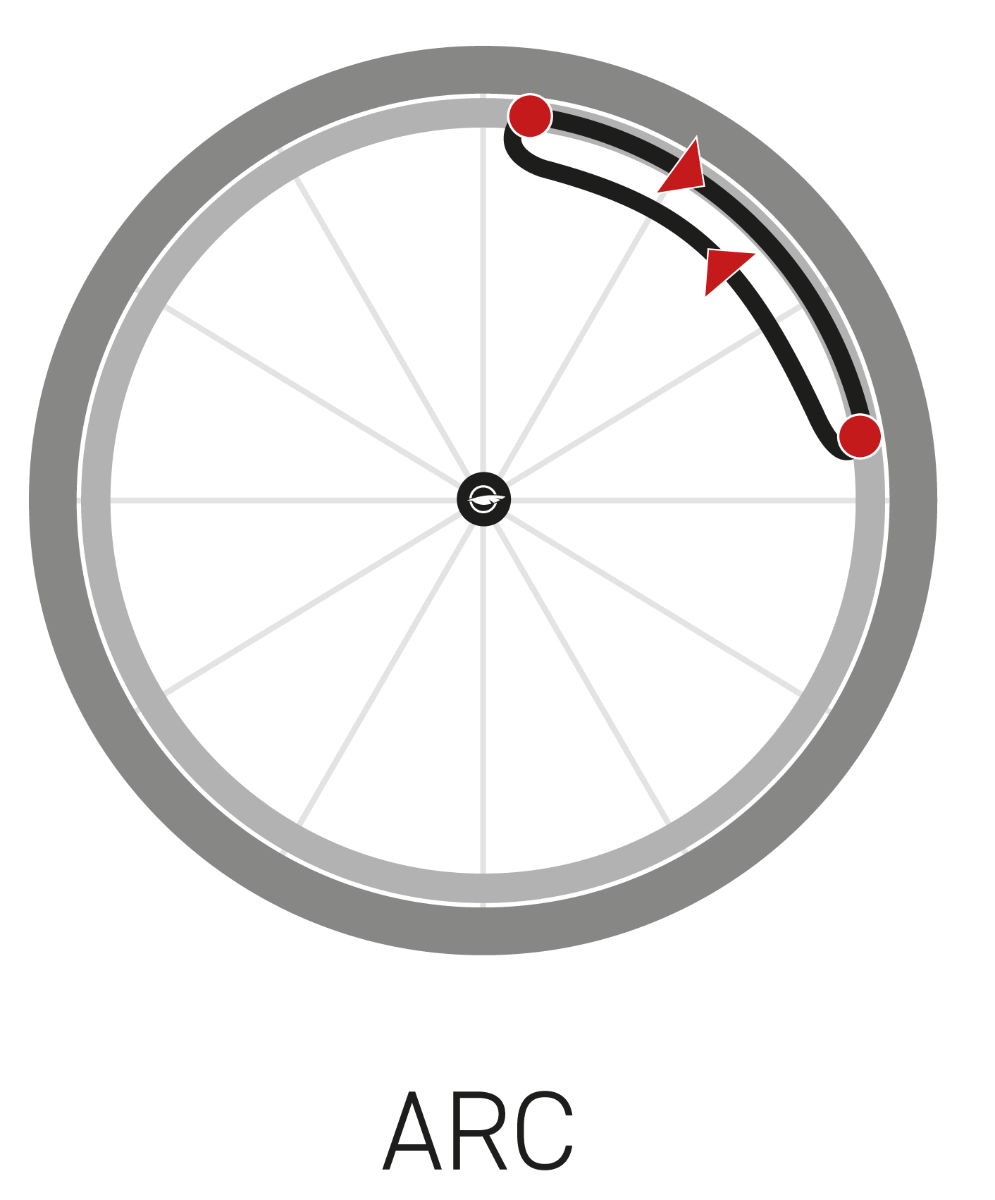

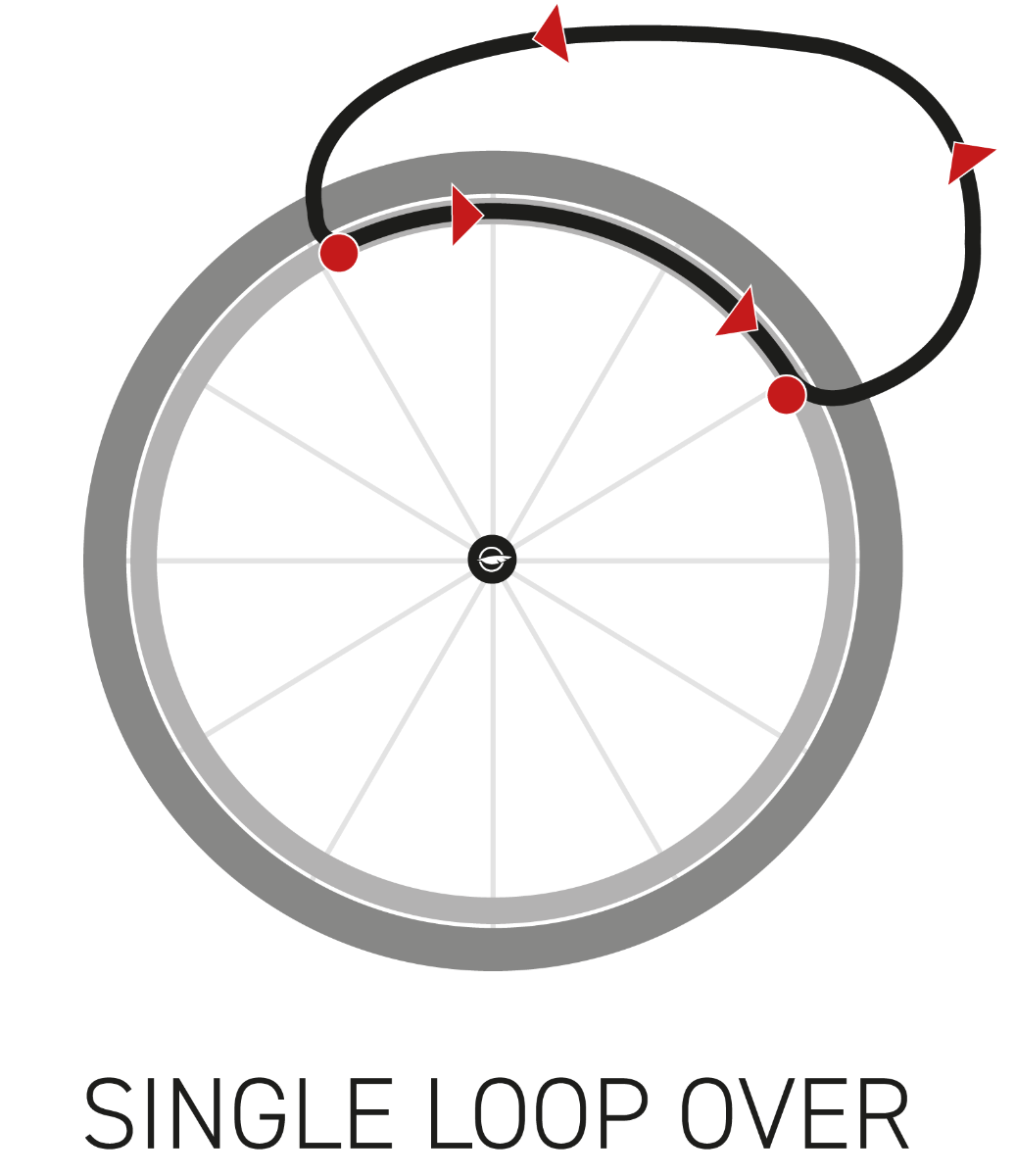

Have the client demonstrate propulsion down a level straight path and pay close attention to the way the hand strikes the push rim, releases the push rim, and the path the hand takes to reset for the next push. The following images demonstrate common propulsion patterns. The red dots demonstrate where the hand makes contact with the rim and where the hand releases. The forward arrows along the black line demonstrate the path the hand takes during propulsion. The reverse arrow path demonstrates the path the hand takes to recover back to the starting point, a very important and often overlooked part of the stroke.

Observe your client’s propulsion patterns, educate, and reassess. Ideally, they will self-select the semicircular stroke for general purposes and arc stroke for uphill travel. Watch posture, shoulder movements, and hand placement. Educate clients on the dangers of poor propulsion habits. Small, mindful changes can make a world of difference in maintaining independence and shoulder health.

To effectively maximize propulsion, consider wheelchair configuration, options selected, and propulsion skills. Identify deficits and make a plan for improvement. When it comes to propulsion, it’s not just about going farther, faster, it’s about injury prevention. For many wheelchair users, shoulder injury happens gradually over years of transfers, pressure reliefs, and propulsion. As with any care provided, the goals of wheelchair prescription are to maximize function, minimize fatigue, delay or prevent dysfunction, and maximize quality of life.

Support your clients’ goals with highly adjustable ultra-light weight wheelchairs dialed into their specific needs.